The Offshore Windfarms

The Next Saga in Deliberately Planned Inefficiency

Electric power generation by positioning windmills along the eastern and western coast lines of the United States as proposed by the Biden administration is another deliberate attempt to drive up the cost of electric energy and drive down the standard of living of Americans. In this article we will layout the case in simple steps and with operational data derived from the offshore installations in Britain and America. One does not require to have a technical background to understand the issues involved and to readily come to the same conclusion of this article. However, one needs to understand some of the details to appreciate the backwardness of investing in windmills for electricity generation. As the saying goes, the devil is in the details.

First, the basics

Electric energy generation with windmills obviously depends on the continuous presence of wind and that is not a reality on earth. The atmospheric wind aided by the rotation of the earth and the heating of the atmosphere and the resulting temperature differences by the sun can never be consistent or reliable. The wind speed is not a constant either. What does that mean to windmill performance? It will also fluctuate, higher the wind speed closer is the electric generation to its capacity and lower the wind speed, lower is its generating level. The windmill will become inoperable at wind speeds exceeding 40 MPH. At the low end, its generating level drops to zero when the wind speed goes below about 7 MPH. The reason for the high windspeed limit is the exposure of the turbine to its mechanical integrity limit. A brake is engaged to prevent windmill operation at high wind speeds.

Another factor about the electrical energy generation is that there is no large scale and economical storage mechanism available. The closest is battery banks but they are generally not suitable for large scale operations. What this means is that the generated electric energy must be consumed instantaneously when connected to a grid. Windmill electric generators with their intermittent, unreliable, and uncontrollable output of electrical energy connected to the electrical grid introduces and imposes severe grid management problems, teetering between rolling blackouts at one end and excessive line voltage at the other end that could cause damage to the devices connected to the grid on the consumption side. There is no smoke and mirror solution to those hard problems. Either the load needs to be shed or generation must be curtailed. Connecting windmill electrical generators to the grid is deliberately introducing instability to a vital energy supply whose demand is projected to increase significantly because of the electric vehicles being pushed into the market and the increasing number of personal electronic devices. We are told that it must move forward because we are solving the “climate change’ catastrophe by switching to windmills and solar panels, which do not require fuel burning and the consequent emission of a greenhouse gas, CO2. We have addressed in an earlier newsletter, “Carbon Dioxide- A pollutant?” the falsehood of that premise.

One more detail to keep in mind here. The battery banks are not the panacea for making the windmill generated electric energy more efficient. The energy produced by the windmills is controlled by the prevailing wind conditions. The battery banks, if used at each windmill, will enable a smoother output of electric energy and not a greater level of electric energy. In other words, one must invest additional capital and operational expenditures to iron out the volatility of the windmill electric energy production. It just increased the cost even more.

Windmill generator- rating deception

If you read any news source, any sales pitch for windmill electrical generators, you will come across quotations of a windmill generator of such and such MW (Mega Watt) rating. The news article will go on to state that a proposed windmill farm (consisting of many windmill generators) will produce X-MW of electrical power and will usually tout that that would be enough to power Y-number of houses. That statement is blatantly wrong. Let us take the case of a single windmill generator whose advertised capacity is 2MW. A MW is one thousand kilowatts.

Need to distinguish between the terms power and energy. Power is the measure of rate of doing work. For example, most people have heard about horsepower, especially referred to the size of an automobile engine, as so may horsepower. MW and KW are electrical equivalent of the rate of using (or, generating) the energy. Energy, on the other hand, is what will be needed to exert the power. In the conventional automobile, the heat energy released by burning the gasoline is converted into mechanical power at the wheels. Measure of energy is different from that of power, which is rate of consumption of the energy to achieve a desirable end. A 2-MW rated windmill can only produce that power at a particular condition of windspeed and optimum orientation of its turbine blades to the wind stream. Let us say for illustrations purposes, that our 2-MW rated windmill is designed to produce that nameplate rated power when the wind speed is at 35 MPH and the Windstream flowing past the blades consists of a uniform stream tube perpendicular to it. As one can imagine, it is an ideal that can happen but sparsely. Wind stream usually will have variations of both the magnitude and direction. What this means is that generation of its designed and advertised 2-MW can only happen sporadically and we have no control over it. So, using the 2MW rating to imply that it can be realized 24/7 and 365 days is a deception. Windmills fall way short of their advertised ability to generate the electrical power continuously. Windmills have a capacity factor problem. We will look at what that is based on the operational experience of the British windmill farms.

An electrical generating plant using coal, oil, gas, or nuclear fission reactors, on the other hand can generate its nameplate rated power continuously, controllably, and reliably for two years before requiring a scheduled maintenance outage. The capacity factor for any of those electrical generators is near 100%. The capacity factor is calculated as a percentage of what the unit can actually produce in a year, or a month compared to what the nameplate rating says it could produce in the same time interval.

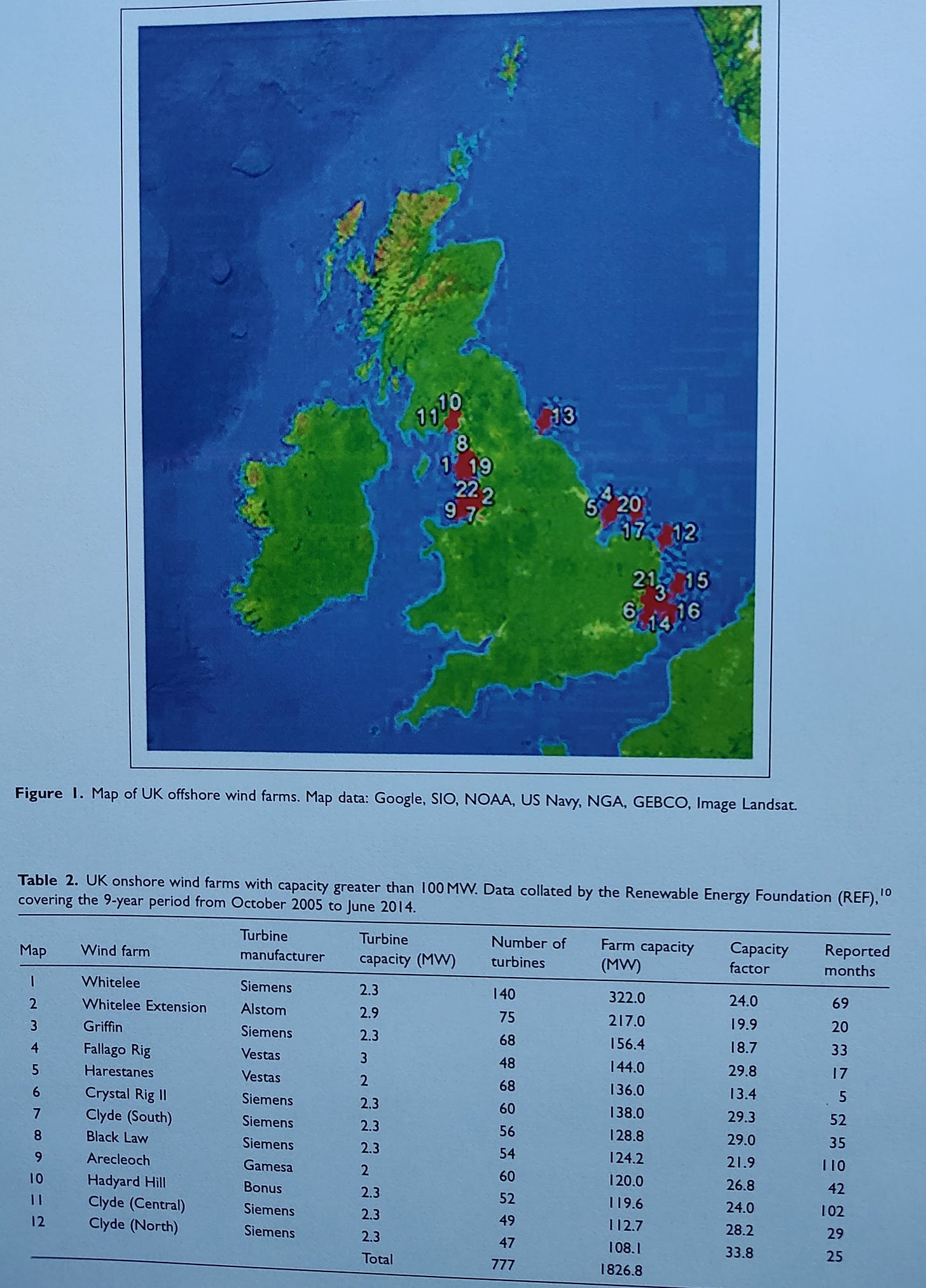

Figure 1 (Top) Offshore windfarm installations; (Bottom) Onshore windfarm capacity factors (Taken from the Reference 1)

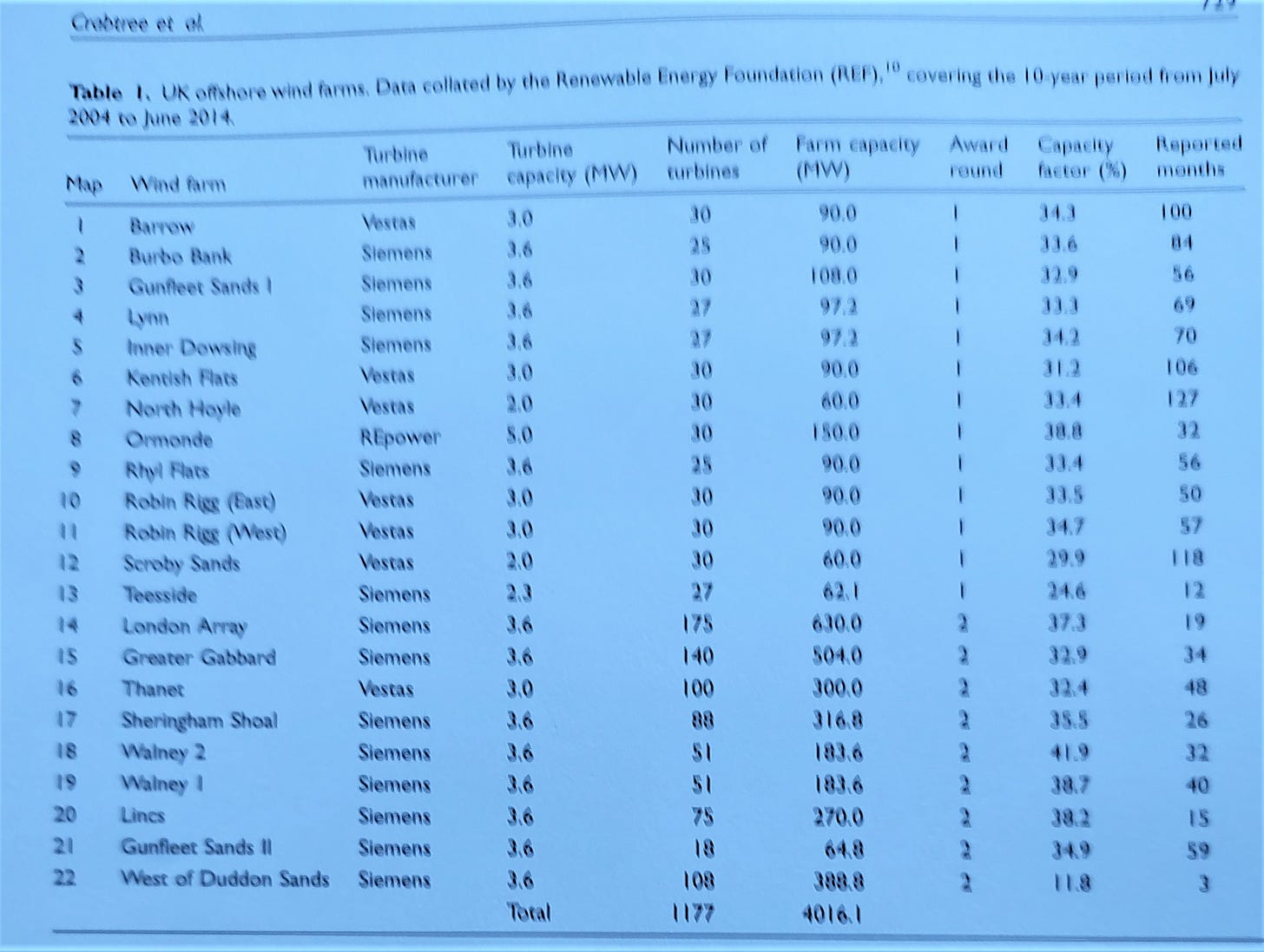

Figure 2 - Offshore windfarms (UK) capacity factors (From the Reference 1 paper)

Windmill generator capacity factor – spells inefficiency

Britain has been operating windmill farms since the 1990s and have accumulated significant operational experience. (Wind energy: UK experience and offshore operational challenges by Christopher J. Crabtree, Donatella Zappala, Simon I. Hogg; Proceedings of the Institution of Mechanical Engineers. Power and Energy, Volume 229 (7), 2015.). In Figure 1 (top) offshore installations in Britain are shown. In Figure 1 (bottom) the capacity factor for wind farms onshore is around 25%. In Figure 2, the capacity factor for offshore installations is generally around 30 %, some higher. An offshore wind farm, Gunfleet Sands 1 shown in Figure 2, with the installed nameplate rating of 108 MW, which is derived by operating 30 windmills, each with a nameplate rating of 3.6 MW can only generate energy at 32% of its nameplate rating. In other words, if we had set up a natural gas combined cycle plant or an oil-fired power plant, its nameplate rating only needs to be 35 MW to generate the same amount of electrical energy, in a month or year. Moreover, those thirty-windmill cluster cannot be located in a stack. They need to be sufficiently dispersed so that disturbance to the Windstream created by one windmill will not affect the Windstream entering its neighbor. The area requirement for setting up a farm of such 30 windmills is necessarily enormous. Comparatively, the footprint of the equivalent 35 MW conventional power plant will be a fraction of that area occupied by the windmills.

In Figure 1(bottom), the onshore windmill farms typically have a capacity factor of 25%, lower than the offshore installations. A major reason for it is that onshore wind characteristics are affected by the land and its features, some natural and some man-made. In addition, since the windmills require generous level of isolation from one another, it is very difficult to achieve it with the available land area onshore. The individual rating of a windmill listed in that figure is less than the 3MW listed in the offshore installations. That is because, the onshore installations were developed earlier, and they represent the earlier technology of the wind turbines.

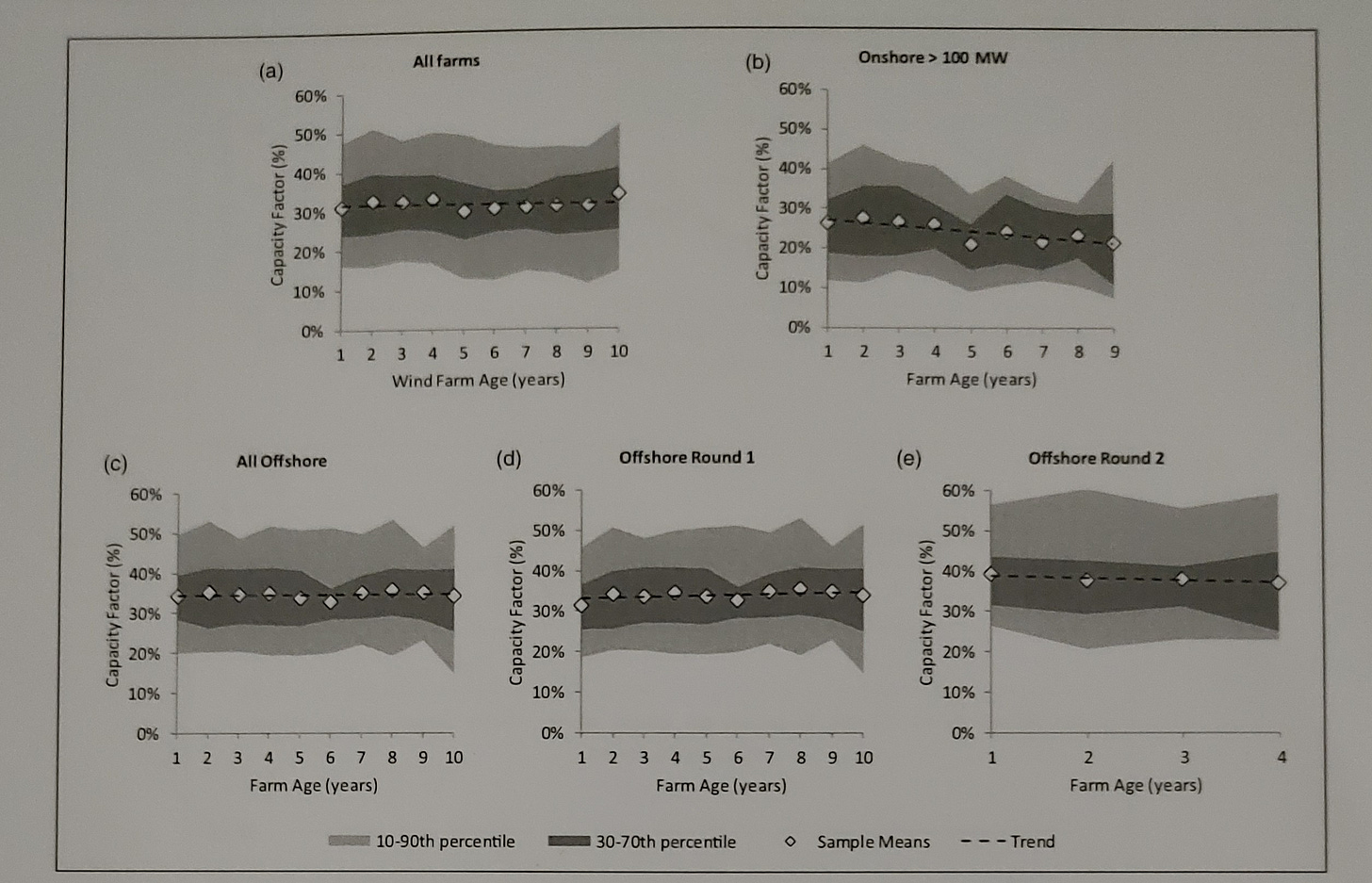

Figure 3 - Capacity factors, onshore and offshore and age (From the Reference 1paper)

Figure 4 - Comparison of capacity factors of all types of windfarms (From the Reference 1 paper)

According to that article referenced, windfarms are being moved to deeper waters and further into the sea to gain on the capacity factor. Figures 3 and 4 (from that referenced paper) illustrate the gain in capacity factor with the newer offshore installations extending further out into the sea. It is about 5 or 6 % gain. Let us just point out here that the capital cost of installing a bank of 30 windmills to produce electric energy in deeper waters and the cost of maintaining them go up exponentially as the depth increases with distance. Imagine that you have 30 individual windmill installations that are all electrically connected and with substations and underwater power cables running several miles to the shore and then to the nearest grid connection point. Each windmill farm represents operational mechanical and electrical units of several independent windmills presenting reliability and maintenance complexity. Reliability of multiple units would always be poorer than the reliability of an equivalent single unit.

One other thing that we need to understand about the capacity factor. A capacity factor for a wind farm of 30% does not mean that it would produce its rated energy 8 hours a day, in a 24-hour period, every day. The wind farm production depends on the prevailing wind and that means one day it may not produce anything, the next day it may have a varying production from zero to rated, and the following day it may only produce in a random manner up to half of its rated capacity. The energy delivery to the grid is unpredictable, uncontrollable, and unreliable even when it is only delivering a fraction what it is designed for.

Wind turbine sizing -reaching its limit

A typical wind turbine is rated 3-4 MW. For comparison purposes, a typical cogeneration type gas turbine-generator installation is 100 MW. In order to have the same level of nameplate rating, 25 to 30 such wind turbines will be needed, arranged in a cluster. The offshore installations frequently line them across the adjacent shoreline so that each turbine will have an undisturbed wind stream. Those multiple turbine installations must be connected electrically with integrated control systems to deliver that energy through electrical cables laid on the seabed to a shore location where proper grid connection could be made. Multiple units comprising the total operating unit always suffer from reliability problems. Wind turbine output capability is being increased with newer equipment. The largest utility type offshore wind turbines in operation today are 8.5MW units. Still larger models are being proposed. GE, 12MW turbine, the Haliade-X, with 320 feet blade length is proposed, locating it at about 850 feet high which is about two-thirds the height of the Empire State Building. Siemens is scheduled to install turbine rated at 15MW with blade length of 110 meters (about 360 feet) at the Dominion Energy’s 2,600-MW Coastal Virginia Offshore Wind Project. The turbine output cannot be increased much further as the physical design limitations are being approached. Just stop here and think about this. A 350-feet length blade at its tip will travel over 4 tenths of a mile during just one revolution of the blade. If that turbine rotates at 10 revolutions per minute at the prevailing windspeed of 35 MPH, the tip velocity travels 4 miles per minute or 240 MPH! Another thing about the effect of windspeed on power generation is, once it reaches its nameplate rated power at a certain prevailing wind speed (say, 35 MPH), that would be the maximum regardless of the prevailing wind speed increasing over 35 MPH. The turbine is equipped with a brake to shut it down beyond certain windspeed, typically 45 MPH. The wind turbine blades are aerodynamically designed, and the tip speed ratio is a big factor. The tip speed ratio is the ratio of the tip speed to prevailing wind speed. In our example above, with the 350 feet length blade, the tip speed ratio at the maximum design point would be 240 MPH divided by 35 MPH, about 7. Whether that is good or bad depends on the aerodynamic design of the blade and its ability to prevent turbulence.

The Coastal Virginia Offshore Wind Project is being constructed some 27 miles off the Virginia coast and will consist of 178 turbine installations. Dominion Energy touts that it will power up to 660,000 homes. It doesn’t tell you that the capacity factor will probably be in the 35% range. What does that mean? The name plate rating of the wind farm of 2,600 MW will only produce equivalent of a thermal or nuclear power plant of 910 MW. That is the rating deception!!! The current estimated cost for the project is $9.8B and it is not clear what the state and federal government subsidies are for it. There are other cost issues about operating an offshore wind farm. We will look into those. But, before we do that we need to understand what the maintenance issues are and for that, we turn to the referenced British paper to gain a level of calibration on that data.

Offshore windfarm maintenance

The British experience as stated in that referenced paper is that the electrical maintenance is generally shorter in duration than dealing with mechanical issues. One could easily understand the level of complexity imposed by having to replace a blade or the gearing with the unit standing several hundred feet above the water surface. The prevailing sea conditions, if not calm would also add to the difficulties and delays. According to that referenced paper, the maintenance records are closely held secret and not a lot of reliable data exist. The paper does outline the expected maintenance time needed for electrical and mechanical issues. Based on their study the authors report that failure rate for the power module runs about 30% of the overall downtime, hours per year. The rotor module follows closely at 25% and is followed by the control system at about 10%. The rest such as the drive train module, auxiliary equipment and structural module round out the other remaining percentage hours spent in maintenance.

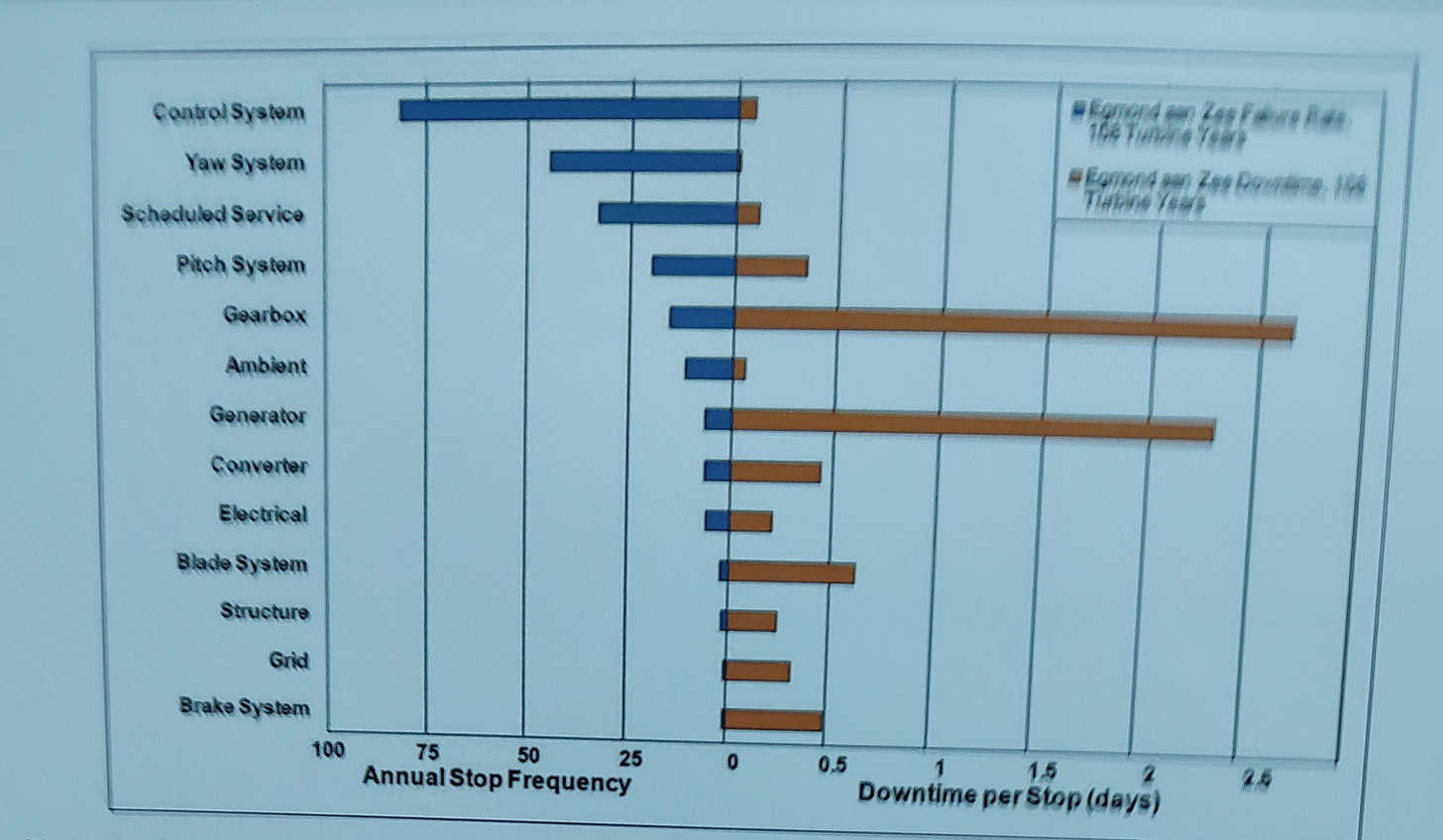

Figure 5 - Component reliability history (normalized) - (from the Reference 1 paper)

Figure 6 - Component reliability frequency and the corresponding downtime impact (From the Reference 1 paper)

Figure 5 lays out the component reliability history, but the actual numbers are not available. A reason that is advanced for that obscurity is protection in a competitive industry. Figure 6 shows the frequency and the corresponding down time estimate for each of the major components of the windfarm installation. The data is not complete since it only represents a three-year period while the life quoted in the contracts is 20 years. Maintenance without having a scheduled maintenance intervals to assess the condition and fix the incipient problems before they force a shutdown will only lead to worse operating reliability. That problem becomes much bigger as the farm frequently has tens if not hundreds of individual wind turbines operating. For example, in the proposed Dominion Energy offshore installation off the cost of Virginia, 178 separate wind turbines will be required to operate. As can be imagined, units going offline due to mechanical or electrical failures will only add to the problem of grid stability over and top of their unreliability by design.

I also reference another informative and detailed paper on the economics of the offshore wind energy. It is: “Out to Sea: The Dismal Economics of Offshore Wind” by Jonathan A. Lesser of the Manhattan Institute, August 2020. In that paper, the author points out that the Block Island Offshore Windfarm, the first US offshore windfarm located 4 miles south of the Block Island, off the Rhode Island coast went into operation in 2016 with five 6-MW turbines. It was shut down in 2020 due to exposed underwater transmission cable due to erosion. Repairing and reburying the cable was expected to take at least six months. The farm output would be zero during that period.

Another major problem with the windfarm is the level of its annual performance degradation. In that referenced paper, the author quotes a study by Gordon Hughes in 2012 and updated in 2020 on the quantification of the annual performance degradation. Based on that study, the newer offshore installations were suffering annual performance degradation of 4.5% per year for units installed after 2011. It suggests that larger units suffer greater level of annual performance reduction. The British paper was not that noteworthy about the performance degradation that they had catalogued. In any event, performance degradation without corrective action (meaning maintenance actions and the downtime that goes with it) would simply mean lower and lower output even at its low-capacity factor to start with.

All the offshore contracts here in the US and in Britain seem to center around a life span of twenty years. Compare that to the power plants operating with conventional fuels and nuclear. Those plants operate at least 40 years or more without having to decommission them. For example, the Japanese government announced recently that they were extending the life of their nuclear power plants to 60-years while they are engaged in constructing and bringing online newer design nuclear power plants. What this means, the capital costs of the windfarms would have to be recovered in twenty years along with the costs of decommissioning those plants.

Costs of offshore wind farms – at least three times a natural gas-fired plant

Offshore wind farm generated electric energy will be the most expensive form of generating electricity. There are several easily discernable factors that point to that inconvenient conclusion. The economy of scaling has reached its saturation point. The wind turbine sizing has reached its limit with 12 to 15 MW nameplate rating. The blades have grown in length to that of a football field or longer. The siting to achieve higher capacity factor is pushing the installation into deeper waters and farther from the coast. Installation costs increase rapidly as the foundations of the towers need to be deeper and be able to support the generator assembly at a higher point to maximize wind capture. A 100-MW farm even with the latest technology designs, will required 8 or more individual installations. The transmission cable would have to be buried in deeper ocean beds and for longer distances. The life expectancy of these units is 20-years. As we discussed above the maintenance costs would have to be factored into the total cost and that can be a significant factor as the units age. There is also output degradation with age and by at least one estimate, the larger units suffer greater percentage of annual performance loss. The performance loss would translate into lower delivery of energy and lower revenue.

In the British paper referenced here, the installed cost of an offshore wind farm is £3M/MW. With $ exchange rate at about 1.3, that would be nearly $4M/MW. The offshore wind installation contracts typically talk about LCOE, Levelized Cost of Electricity. It represents all costs associated with the project (installation capital costs and all the operating costs) spread over its life, 20 years, equally. “Installed capital costs include construction costs, financing costs, tax credits and other plant-related subsidies or taxes.” Operating costs include expected maintenance costs, taxes and subsidies. The British experience prior to 2020 (data not reported after 2020) has been a LCOE of £140/MWh (Megawatt-hour= energy produced) and that is, using the same exchange rate of 1.3, it translates into $182/MWh. In the US, there is very little real data available for offshore wind projects. The only one that has been operating since 2017 is the Rhode Island’s Block Island Wind Farm of 30MW nameplate rating. “The power purchase agreement (PPA) for the project specified that utilities pay a first-year price of $245/MWh for the electricity that it generates; that price escalates at 3.5% each year. (By comparison, in 2016, the average wholesale price of electricity in New England was less than $30/MWh; in 2019, the average wholesale price of electricity was $30,67/MWh, reflecting continued low natural gas prices.) In 2035, the last year of the Block Island Wind Farm PPA, the contract price will be more than $470/MWh”. Several offshore windfarms, mostly supported by New York, New Jersey, and NE states, have PPA numbers that range from $70/MWh to $150/MWh. The Virginia offshore wind farm by the Dominion Energy is the only one sponsored by a regulated utility. The utility will recover all of its costs with a controlled profit margin from its customers and state taxpayers of Virginia. All those numbers are projections over a 20-year period with the assumption of no degradation of output over time which is not a realistic one. Since the operators of these farms (except for the Dominion Energy farm off the coast of Virginia) are developers, it is quite likely that they may shut the operation down when the costs exceed what the PPA terms require and most likely, will demand a renegotiation of the contract pricing. On top of it all, there is no provision according to the referenced American paper, for decommissioning charges following the completion of its life cycle after 20 years. The author points out that the nuclear power plant operators are required to set aside cost allocation for decommissioning after its life. The net result is that costs could become even more prohibitive once the realities of performance degradation with time, actual versus assumed maintenance costs and the decommissioning costs are addressed.

US Energy Information Administration (EIA) within the DOE, ESTIMATED, that offshore wind farms operating in 2025 will have a LCOE ranging from $102.68/MWh to $155.55/MWh and an average of $122.25. “By comparison, the levelized cost of gas-fired combine cycle generating units entering service in 2025 is between $33.35/MWh and $45.31/MWh with an average of $38.07/MWh.” The projected cost of wind farm electricity is over three times that of a gas-fired, reliable, controllable, and continuous generating plant.

In all cases in the US except for the Dominion Energy proposed wind farm, the state governments are entering into contract with the developers to produce and deliver the electrical energy at a price agreed upon in the PPA without requiring any approval by the Public Utility Commission or the utilities themselves. That alone tells you that the electricity generated by the offshore windfarms can never compete on efficiency of generation.

Environmental damage – Offshore and onshore windfarms

It is a proven fact that the onshore electric energy producing windmills kill thousands of raptors, bats and other birds. Nuclear power production or gas or coal fired power plants do not kill birds or animals so that we can have the electricity we demand. Oil spillage from tankers have killed waterfowls but they are neither common nor frequent occurrence. We surely know about it because the environmentalists who are green on the outside and red on the inside and their allies in the mainstream media amplify it. One just wonders why the same environmentalists who are so much attune with the environment give the windmills the pass when they cause so much destruction to the birds.

The windmill farms require enormous acreage to generate unreliable, uncontrollable, and intermittent electric power compared to the conventional power plants. For example, the Diabolo Canyon power plant (the only one allowed to operate in CA) consists of two units generating 2,256 MWe at a capacity factor of 99% for unit #1 and 88% for unit #2. They occupy 12 acres. PG&E, the utility operator owns over 12,000 acres and had designated 300 acres for the plant perimeter. The cost of electricity produced by the two units is 6 Cents/KWhr. Which is less than the 10 Cents/KWhr of the PG&E system.

The Dominion Energy proposed Virginia offshore windfarm with 2,600 MW nameplate rating operating at 35% (expected, not realized) will have 178- 15MW windmills scattered over 72 acres or more, 27 miles offshore. They are expected to produce equivalent of a 910 MW nuclear, coal or combined cycle power plants in a haphazard manner. Wind turbines occupy more space to generate what the conventional power plants require.

The offshore wind turbines with their super long blades are expected to generate noise. One of the reasons that the state and the federal governments are pushing offshore windfarms is because of the opposition to the onshore installations generating unhealthy noise pollution. Whales and other sea-mammals rely on propagation of sound in the ocean to communicate. Installing offshore windfarms is bound to interfere with the survivability of whales. As it is, the right whales only number about 300 worldwide and this kind of noise pollution that never existed before can further endanger that species. None of the environmental groups who were so adamant about saving a species of fish that they forced the dismantling of hydroelectric dams have even raised a protest with the potential extinction of the right whales due to the offshore windfarms.

Major components of the wind turbine are not recyclable. Turbine blades have materials in them that cannot be recycled. The rare earth mining for those components is located in China with very little requirement for the protection of the environment. Ore tailing and other discarded materials are washed into the local rivers and lakes. Manufacture of some of the components in China involve slave labor. Cobalt mining in Africa, run by the Chinese companies employ child labor and cobalt is a key ingredient in the windmill and battery manufacture. As demand for these components go up, the pollution and unhealthy working conditions would increase in those places. Where are the Sierra Club, the Nature Conservancy, or the Audubon Society?

Biden Administration and Offshore fantasy

Biden administration has signaled as a part of its drive to net zero stupidity to open the east and west coasts for positioning the offshore windfarms. One such proposal calls for 30,000MW windfarm spread over 365,000 acres. As we discussed before, the nameplate rating of 30,000MW could only yield about 10,000MW equivalent in electrical energy production. Even that fraction of the output will be haphazard and cannot be well defined as wind conditions are not predictable in advance- may be two or three days in advance and even that not reliably to run the grid. The cost of electricity will be prohibitively expensive. Another major reason that cost will be exorbitant, is that the utility or the grid operator must have conventional power plants on standby alert to pick up the slack when the wind dies down. In essence, you will be producing about 1/3rd but you will have additional capital and operating expenses on a standby.

A 900MW nuclear such as the Diabolo Canyon Unit #1 with its 12-acre footprint will carry the same output and with no needed backup power plants. Its capacity factor can be nearly 100%.

It is not because these people don’t understand the dismal situation they are creating. They are convinced for a variety of reasons that the standard of living in America must come down necessarily to combat “climate change”, aka man-made global warming due to CO2 levels going from 300 parts per million to 500 parts per million based on the assumption that the fossil fuels are causing it. There is no scientific data for any of it other than the measurement of the atmospheric CO2 levels and simply assigning it all to the human activities and simply assigning the warming trend to the measured levels. Many pushing this are also doing it to eliminate personal freedom and its byproduct, capitalism. Many are clamoring for socialism, fascism or old-style feudalism where a few own and control everything and the rest are just serfs under their employment. Some want to see a huge reduction in human population as a necessity for sustainability and reducing the human population to the lowest survival mode would achieve that goal. Inexpensive and accessible electrical energy must be done away with to reach that goal.

References:

1, Wind energy: UK experience and offshore operational challenges by Christopher J. Crabtree, Donatella Zappala, Simon I. Hogg; Proceedings of the Institution of Mechanical Engineers. Power and Energy, Volume 229 (7), 2015

2. Out to Sea: The Dismal Economics of Offshore Wind” by Jonathan A. Lesser of the Manhattan Institute, August 2020